Ice-flake making machines find utility in many market segments. Depending on the nature of applications, the best ice making machines generate types of ice such as cube ice, flake ice, nugget ice etc. in huge amounts daily worldwide.

These ice types cater to the varied requirements ranging from preservation of aquatic produce to stem cells storage.

Flake ice is perhaps the most efficient form of ice from a diverse utility standpoint.

Here is why:

What is Flake Ice?

Flake ice is a light, airy, moldable form of ice that can stick to itself. Flake ice maker machines generate this ice at temperatures varying from -5°C to -8°C.

Flake ice is easier to work with and it finds diverse applications over numerous fields (like fisheries) as discussed ahead.

Flake Ice Machine for Different Industries

Food Processing

- Dairies

Ice flake machines are used in cooling storage tanks & the icing of the delivery trucks of the dairy industry to preserve milk products like cheese, yogurt, butter, cream & ice cream. These products are temperature sensitive and require appropriate temperatures to prolong their shelf lives.

The milk is stored for at most 2 days at below 40°F temperatures in the cooling storage tanks after which it undergoes homogenization, pasteurization, packaging & shipping. The chillers arrest deterioration of the milk molecules, facilitating the manufacturing of above mentioned dairy products from it.

- Fruits & vegetable produce

Maintenance of freshness of fruits & vegetables till they are bought by the customers is a big challenge in this industry. Wrong temperatures may damage the produce or, worse, cause it to rot.

On-farm flake ice maker machines come to the rescue. Due to the relatively larger contact area of the flake ice and lesser sharp edges, the harvested produce can be cooled exceptionally fast without any significant damage to the surface of the fruits or the veggies. Before shipment of the pre-cooled produce, flake ice is used in top icing to ensure preservation of the produce’s structural integrity & freshness.

- Fisheries

As seafood resources are depleting, fishermen are making longer fishing expeditions which makes it critical to have flake ice making machine on board the ship to preserve the fish for longer times since fishes start decomposing rapidly immediately after getting caught. This demands that the fishes be kept uniformly at around 0°C which is easily accomplished by the flake ice produced by the machine onboard the ship. Due to its soft nature, the flake ice doesn’t bruise or injure the fish during storage and it keeps the haul fresh at every level of the supply chain till it arrives at the local market.

Land-based seafood processing plants, storage facilities etc. also employ flake ice making machines so that no unchilled fish is accumulated at any point of time.

Food Displays

Flake ice is soft, moldable & uniform which makes it best suited for creating appealing displays. It is an excellent choice for retail displays like seafood counters at supermarkets. Supermarkets employ flake ice machine for fish, fruits, veggies & a lot of other food items that must be consumed within a short period.

Passively refrigerated open beds are also used in supermarkets for presenting the produce to the customers. Food products must inspire trust among the customers about freshness. The food items are nestled in flake ice displays which are good for aesthetics as well as cooling.

Due to the softness of the ice flakes, there is no risk of blemishes on the food items. The snow like texture of the flakes & their easy molding ability renders the ice flakes highly useful in blanketing perishable items like seafood on display in any shape one wishes for.

Buffet displays are cooled efficiently & evenly by the flaked ice. As the contact area of flaked ice is larger, it lasts longer.

Confectionery

Just like the dairies, a confectionery also needs a flake ice machine. In order prevent the flour from leavening during the mixing of flour & milk for baking a confectionery item such as cake or pastry, flake ice is used as an ingredient. Its thinness allows it to melt quickly, completely & evenly so that no air pockets remain in the mixture. This prolongs the life of the batter. On the other hand, using chip ice often results in uneven cooling of the batter, residual ice & air pockets in the batter.

The flake ice is best suited to control yeast growth during the production of bread. Owing to its even melting behavior, easy handling as compared to handling chilled water, & excellent cooling qualities, it is widely used in the production of pies, pastries & pasties.

Medical Sector

The medical sector uses refrigeration not only for vaccines but also to preserve and store organs & stem cells. For the latter purpose, flake ice serves best. Also, the medical staff uses flake ice to treat sprain and other related injuries.

There are many other applications of flaked ice.

As flake ice has larger contact area, it provides an excellent way for rapid cooling of the laboratory work. Its easily moldable nature makes flake ice the perfect choice for use in physical therapy treatments like ice baths & cooling packs, although more relevant for ice baths since the residual water content of flake ice has more adhesive nature. This makes it suitable for use in processes where faster heat transfer is the requirement.

Construction Sector

A relatively unknown fact is that concrete mix also requires the right temperature during its transportation and usage. Flake ice in concrete cooling process is used as a direct source of water to reduce cracking of concrete. The ice is mixed and poured at constant and low temperature in the mass concrete mixture which finds utility in projects of hydro dams, nuclear power plants etc.

When the concrete is cured, it generates lot of heat. Flake ice is used to reduce & control this heat thereby regulating the temperature of the concrete mix at the desired level for specific construction projects. If the temperature of the concrete mix is not regulated, it can compromise the structural integrity of a project.

Flake ice, being thinner, melts quickly in the concrete mix & leaves no large ice particles or voids, which is usually the case if chipped ice is used. Due to its adhesiveness and longer life, flake ice is the ideal choice when the concrete production has to be delayed for some reason.

As the flake ice production doesn’t require excess water disposal, the ice flaker machine can be set up quickly and in a little space near the construction site.

Hospitality: Bars & restaurants

The hospitality industry is all about aesthetics & ambiance of the place & freshness of the food dishes served.

Salads, seafood bars, drink displays, cocktails, drink tubs, fruits juices … flake ice makes these delicacies only better at restaurants and bars. The moldable flake ice is ideal for use in seafood bars. One can create eye-catching shellfish & raw fish selections using flake ice for customers.

High end restaurants employ the best flake ice machine for stocking quality flake to create dazzling food presentations in front of the customers.

At bars, bottles of beverages & cans stay in place amid the flake ice sticks (owing to flake ice’s moldable nature) and remain cool for a longer time. While blending the beverages, the crushed hard ice cubes can not only damage the blenders but also takes time to melt during which bartenders can serve more customers at quicker pace. Flake ice machines are simply faster & have better reliability.

Where Can I Get A Flake Ice Machine?

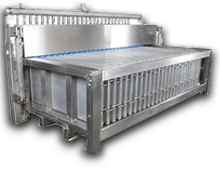

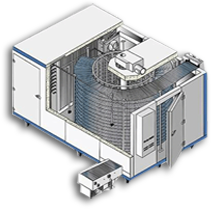

Industrial Refrigeration Pvt. Ltd (IRL) are pioneers in promoting scientifically designed, highly reliable & energy efficient flake ice systems in India.

IRL offers some of the best flake ice makers with capacity ranging from 1 ton/24 hours to 100 tons/24 hours. Industrial Refrigeration designs & erects refrigeration system in ammonia or Freon 404A incorporating the flake ice generator.

Our flake ice maker machines find application in wide ranging fields like aquatic food processing, medium and large chain supermarkets, food processing, medical facilities, concrete cooling, dye industry etc.

Feel free to contact us here for the best solution to your flake ice maker machine requirements.