Individual Quick Freezing (IQF) is a technology for freezing individual units of a product while keeping them separate from each other, unlike the bulk freezing of product by cold store freezing. For instance, freezing a batch of peas or berries in cold storage results in their clumping, which doesn’t happen in an Individual Quick-Freezing Machine.

Whereas cold freezing is used for large volumes of bigger sized products, IQF processing unit is ideal for rapid freezing of smaller products (peas, berries, pasta, small fruits, cheese etc.).

Fluidization Process in IQF Freezing

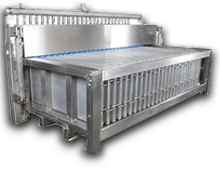

IQF freezers incorporate a fluidized bed freezing system, where particles (e.g., peas or berries) become fluidized—moving in a fluid-like manner—when extremely cold upward-flowing air exerts high drag against gravity.

This results in rapid freezing with minimal ice crystal formation, preserving the product's structure. For this reason, IQF machines are widely used in the seafood industry.

Types of Fluidization Used in IQF Freezing

There are three main types of fluidized bed freezing used in the IQF industry. These are employed at different stages of the freezing process across various products like seafood, fruits, and vegetables.

1. Circulating Fluidization

This type lifts the product units completely from the freezer bed with a strong, cold airflow. It is used in the initial crust-freezing stage.

2. Bubbling Fluidization

Also known as a semi-fluidized bed, this type uses a gentler airflow that only partially lifts the product. It is used in the second stage of freezing.

3. Fixed Bed Fluidization

Used in the final stage, this method keeps the product on the bed. It is ideal for brittle products that cannot withstand suspension in airflow.

Importance of Fluidization in IQF Freezing

Fluidization ensures individual product units remain separate, aiding faster and more uniform freezing. Products vary in texture, water content, and brix level, requiring customized fluidization settings for optimal results.

Correct fluidization maintains product nutrients and texture, and accelerates freezing, reducing dehydration. In IQF, dehydration is limited to 0.3–2%, compared to up to 10% in cold storage freezing.

Ensuring the Right Fluidization

Key factors in achieving correct fluidization in an IQF machine include:

- Fans: Vane axial fans with frequency conversion allow adjustable airflow. Machines without this feature must bypass extra airflow, wasting energy.

- Bedplate Design: Pressure drop across the bedplate depends on fan strength and plate design. Hole size and distribution affect performance.

- Freezer Body Aerodynamics: Fewer internal parts and minimal airflow obstruction enable precise control of fluidization for various products.

Why Choose IQF Freezing?

Unlike conventional cold storage, IQF freezing prevents discoloration and clumping. Products freeze individually and maintain their shape and shelf life.

Cold storage often uses boxes and trays that require labor and maintenance. IQF eliminates this need and ensures hygienic, contact-free processing.

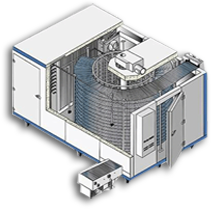

Industrial Refrigeration Pvt. Ltd. (IRL) is a leading IQF manufacturer in India. Our machines feature stainless steel belts with adjustable speed for crust and finish freezing, and include:

We offer capacities from 150 Kg/H to 2000 Kg/H, suitable for freezing up to -35°C for vegetables, fruits, and seafood. Contact us to learn more or set up an IQF processing plant.