Industrial Refrigeration are pioneers in promoting slurry ice systems to process industries.

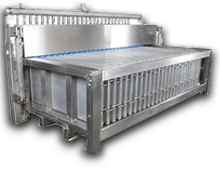

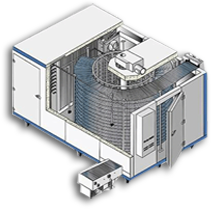

Slurry ice flowable is the mixture of ice crystal and water solution (usually sea water, brine, sweet water or glycol). It is also known as fluid ice, liquid ice, and so on. There are, usually, two ways to make slurry ice. Each way has its own features and advantages. Slurry ice can be made from broken solid ice and mixing with brine or sea water. However, the mixture still contains large and sharp ice crystals with thickness 0.6-10mm. Making this kind of slurry ice requires a large amount of energy, including energy consumption for ice breaking and grinding. Slurry ice can be made in pipe type evaporator. Brine or sweet water is pumped to internal pipe by water pump and the refrigerant circulates between inner and outer pipes. Ice crystal would be formed on the evaporator inner surface, at -8 ~ -12 , and scraped down by the rotary ice scraper. The mixture of water and ice collected is slurry ice. Resulting from the heat exchange of ice phase and high heat transmission coefficient, evaporator size may be reduced eventually.

Application fields :

Slurry ice is commonly used in a wide range :

- Air conditioning.

- Packaging and Industrial Cooling Processes.

- Supermarkets.

- Cooling and Storage of Fish.

- Produce.

- Poultry and other perishable products.

Slurry ice can boost by up to 200% the cooling efficiency of existing cooling or freezing brine systems without any major changes to the system (i.e. heat exchanger, pipes, valves), and reduce the amount of energy consumption used for pumping.

Advantage fields :

Slurry ice is also used in direct contact cooling of products in food processing applications in water resistant shipping containers. It provides the following advantages:-

- Product is cooled faster - the smooth round shape of the small crystals ensures maximum surface area contact with the product and as a result, faster heat transfer.

- Better product protection - the smooth, round crystals do not damage product, unlike other forms of sharp, jagged ice (flake, block, shell, etc.).

- Even cooling - unlike other irregular shaped ice which mostly conducts heat through the air, the round shape of the slurry crystals enables them to flow freely around the entire product, filling all air pockets to uniformly maintain direct contact to cool to the desired low temperature.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Slurry ice systems:- https://www.irl.co.in/products/slurry-ice.html