Industrial Refrigeration offers Machinery to process and add value to food industries.

Hamburger Forming Line can make hamburger patty, chicken nuggets, chicken or beef steak, pumpkin patty, etc. used by KFC, McDonald, Marry Brown etc. This forming line comprises of machines for forming, battering, flouring (pre-dusting), breading, and frying.

Patty Former can fill stuffing materials, & mold, hamburger patty and chicken nuggets, etc. Stainless steel and other special materials for food are adopted for the whole machine to make it conform to the hygienic standards and HACCP standards. It is easy to clean and conforms to European safety standards. It is versatile enough to handle a wide range of raw materials.

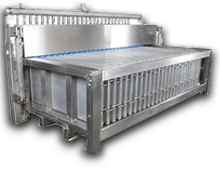

Battering Machine coats the batter on chicken, beef, pork, fish, shrimp and other seafood through four batter curtains and the batter bath on the bottom. Batter delivery pump can feed batter of high viscosity without cutting. It has a reliable safety protection device. Connection with the forming machine, crumb feeder and frying machine enables continuous production. The machine is fully made of stainless steel.

Flouring Machine evenly coats a layer of mixed flours uniformly all over the product on the conveyor belt. Connection with the coater and crumb feeder may form product lines for different products for the sake of various processes such as flour-batter-flour, batter-flour and batter-flour-flour. Forced fan and vibrator remove excessive flour. Removable design facilitates cleaning of whole machine and meets HACCP standards.

Breading Machine coats the breadcrumb into chicken, beef, pork, fish, shrimp and other seafood. Its suitable for both small-size crumb and big-size crumb. It is equipped with frequency inverter, safety protection device and SIEMENS electric parts. The whole machine is made of stainless steel and meets HACCP standards.

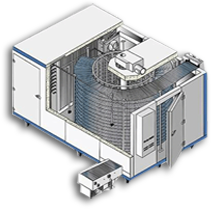

Continuous Fryer can be used to fry all kinds of products, like hamburger patties, chicken nuggets, snacks, pellets, beef steak, fish steak, shrimp steak, etc. With advanced oil-water massif technology and auto filtering function which greatly prolongs oil usage life. No need for frequently changing oil. Temperature is automatically controlled. Double-layer net belt design assures frying space. Advanced mechanical allocation and controls, keeps the machine at continuous good performance.

Features :

- Fully automatic and continuous.

- Small size, easy operation.

- Very easily cleaned.

- This line can process diverse materials such as meat, poultry, beef, mutton, Seafood, fish, shrimp, vegetable, pumpkin, potato, cheese or their mixture.

- Various production procedures can be combined for producing different end-products.

- Various sizes can be made.

- Full stainless steel 304.

- Turnkey project provided from raw materials to packing.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/