Deep Freezer

IRL

Cold Storage

Industrial Refrigeration(IRL) offers Cold Room Systems to food industry.

IRL specialized in design and installation of cold rooms & cold stores. Our experts are available to guide you through each stage of the process from the initial consultation through to the design and then the final installation. This ensures that the cold room you have specified meets with your expectations and requirements.

Design & Consultation : We offer an initial consultation, with design advice, CAD drawings and a full quotation as part of the project package. We can also offer a consultation service for the design of insulation and refrigeration systems, if you wish to appoint your own contractor.

Insulation : All our cold stores in this section are constructed using the latest fire resistant tech rated panels. Rooms up to 10m in height and any combination of widths and depths can be built meaning whether you want to walk in or drive in, we can build a cold room to suit your needs.

Refrigeration : All types of temperature controlled systems can be designed and installed by our engineering department. All temperature ranges from ambient, preparation areas, chillers and freezers can be achieved. We design remote systems using the latest low noise equipment to achieve the temperatures you require. We are pride of ourselves of offering global warranty, service and support and are adequately able to offer annual comprehensive maintenance post warranty.

Floors : A range of floor options including insulated floors with EPS slab & Puf slab for cold room, vapour barrier, Trimix concrete finish larger rooms are all available.

Doors : A full range of door options are available and are manufactured to order which means we can offer any size and type of door you require. Hinged, sliding, rapid roll, crash, flush, incorporating vision panels and windows are just a selection of the products available.

Optional Extras : As part of the design and installation package we can offer racking, lighting, strip curtains, humidity controls, camera and many other additional items.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Cold Room Systems:- https://www.irl.co.in/products/cold-storage.html

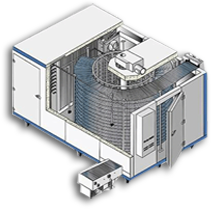

Chilled Water System

Industrial Refrigeration offers Chilled Water System for food, pharma, & chemical industries.

IRL manufactures Water Cooled Screw Chillers incorporating reliable screw compressors from Bitzer (Germany) and Frascold (Italy). These chillers are fully Microprocessor based suitable for process cooling applications from (+) 20˚C up to (-) 40˚C. For lower temperatures of up to (-) 50C look into Brine Chillers. These screw chillers are offered with up to 2 Nos. screw compressors in one machine but having separate and individual refrigeration circuits. These chillers are world class, manufactured in an ISO 9001, certified factory with an option of using CFC free refrigerants R-407C & R-134a complete with in-built Process pump and stainless steel chilled water expansion tank. These chillers are also rated for an ambient of up to (+) 50˚C and cooling tower water temperature up to (+) 37˚C at the inlet of the condenser. The various operating voltages of these chillers are: a) 380 / 400 Volt AC / 50 HZ b) 460 Volt AC / 50 HZ c) 380 Volt AC / 60 HZ d) 460 Volt AC / 60 HZ.

Features :

RELATED ALL TYPE CHILLER The glycol chillers, brine chillers, air cooled brine chillers, water cooled brine chillers and liquefiers offered by IRL are tailor made to suit customer requirement. IRL offers these low temperature Glycol / Brine up to an operating temperature of (-)50˚C for which compressors can be single stage open type / double stage open type / double stage semi hermetic / single stage screw depending on the size and the temperature requirement of the customer. For very low temperature application even Cascade systems are used for quick cooling. The material of construction is selected carefully depending on the application temperature and special alloys steel is used for ultra lower temperature application. These chillers can be air-cooled or water-cooled depending on the customer requirement. These chillers are rated for an ambient of (+) 480C and various operating voltages which are: a) 380 / 400 Volt AC / 50 HZ b) 460 Volt AC / 50 HZ c) 380 Volt AC / 60 HZ d) 460 Volt AC / 60 HZ

Applications :

- Food processing industry

- Accelerating mould of plastic.

- Extending the life-span of mechanical components.

- Electronic industry and ultrasonic cleaning industry.

- Electroplating industry cooling to enhance precision of electroplating.

- Food processing industry cooling to enhance the quality of food.

Advantages :

- Water temperature can be set at random from 0.5 degrees to 20 degrees.

- Intelligence control system can automatically adjust the load increasing and decreasing of the compressor to maintain outlet temperature in certain degree based on water temperature.

- The flow of water varies from 1.5m3/h to 24m3/h, which can meet different needs.

- Containerized structural design, which can be transported to places where refrigeration is needed.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Chilled Water System:- https://www.irl.co.in/products/chilled-water-system.html

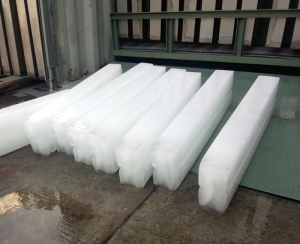

Block Ice Plant

Industrial Refrigeration Pvt. Ltd.(IRL) promote Block Ice Plant to food & other industries.

The Ice Making & Harvesting section of the plant consists of the Brine Tank, an electrically operated Lifting Device (Crane) running on rails along the sides of the tank, a Thawing Tank, a Tilting Device with an inclined Wooden Table to receive the ice blocks as they slide out of the cans and a Filler. Standard Rectangular 25, 50 & 150 kg Ice Cans fit in the brine tank which is covered with solid Wooden Lids as shown on the picture.

Features :

Block ice machine can be installed in different conditions, convenient for transportation. Standard Block ice making plants are available in 9 sizes with a capacity range of 3 to 65 tons of ice per 24 hrs. Depending upon size and customer’s specifications, Plants are designed for either 100 Lb (45Kg) or 300 Lb (135Kg.) capacity cans. Custom-made plants can also be designed for 55Lb (25Kg) capacity cans. Operation system of the block ice machine use PLC control system which is easy for operation and maintenance.

Special request : Water temperature 0.5℃~46℃.

Block ice thickness : Dimension depends on customer's requests.

Refrigerant : R22 , R404A, R507

Applications :

- Supermarket displays

- Frozen food processing

- Construction concrete cooling

- Transportation

- Deep-sea fishing

- Medicine production, chemical industry cooling & ice cooling works

Advantages :

- Block ice feature : Selectable sizes, big density and large cold accumulation.

- Split block ice design : Containerized design and assembled convenience.

- Environmental protection ice moulds : 304 stainless steel, aluminum alloy or PE material

- High production ice : Weight of every block 10kg/25kg/50kg.

- Daily ice making capacity : 1ton-100ton.

Industrial Refrigeration Pvt. Ltd:- https://www.irl.co.in/

Block ice machine:- https://www.irl.co.in/products/block-ice-plant.html

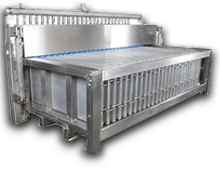

Blast Freezer

Industrial Refrigeration Pvt. Ltd. (IRL) offers Blast Freezer systems to the food industry.

Blast chilling is a method of cooling food quickly to a low temperature that is relatively safe from bacterial growth. Bacteria multiply fastest between +8 °C (46 °F) and +68 °C (154 °F). By reducing the temperature of cooked food from +70 °C (158 °F) to +3 °C (37 °F) or below within 90 minutes, the food is rendered safe for storage and later consumption. This method of preserving food is commonly used in food catering and, recently, in the preparation of 'instant' foods, as it ensures the safety and quality of the food product.

A blast freezer may also be known as a shock freezer. Such freezers are intended to rapidly bring the temperature of foods down, freezing them extremely quickly. These specialized freezers are used in the frozen food industry for everything from ice cream to television dinners and they are also utilized in some commercial kitchens for specialty tasks.

When food is frozen, the water inside it crystallizes. If freezing takes place at relatively warm temperatures, the ice crystals which form will be large. In a blast freezer, the extremely cold temperature promotes very rapid freezing, which creates small ice crystals. The smaller the crystals, the less damage to the food, as large crystals can rupture cells. Once the food has been frozen in a blast freezer, it can be moved to a more conventional freezer for storage, as long as the freezer stays cold enough to keep the food frozen.

Applications :

Freezing into blocks is an effective economical method of preserving, handling transporting and storing perishable products. Horizontal Plate Freezer in one easy operation, ideal for freezing fish, offal’s, fruit puree, fish fillets, shrimp and vegetables.

Products are simply placed into horizontal pockets between the aluminum freezing plates. After freezing, the blocks can be unloaded manually or mechanically onto pallets or a conveyor system and within minutes the whole processing cycle can begin again.

Advantages :

- A small footprint machine.

- Utilizes maximum product capacity in height.

- Designed to freeze a wide range of product thickness.

- Batch loading of product in trays, cartons & frames.

- Air Contact freezing.

- Capacity from 500 kg to 10000 kg.

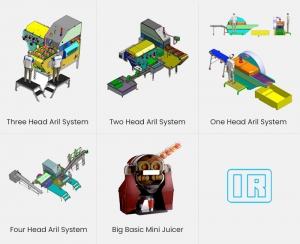

Aril Extraction & Juicer

Industrial Refrigeration is pioneers in promoting Aril Extraction systems to the fruit Industry in India.

Aril System is nothing less than a revolution in bringing the pomegranate, this fabulously health-rich fruit, into the food market and onto people’s plates. Producing in one hour more than ten times the amount previously produced by a worker in 8 hours, Aril System makes Extracting arils not only cost-effectively labor-saving and fast, but also produces a tastier, more hygienic, and generally superior product than ever before possible.

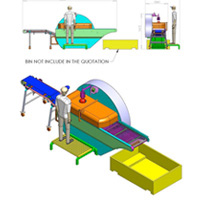

One Head Aril System

Processing rate : 10-15 pomegranates per minute per extractor.

Extractions rate : About 180 kg. Arils per hour, depends on the pomegranates size.

Features : Arils extraction system unit and Water Separation unit

- Manual feeding unit

- The extracting machine

- Air/Water separation unit

- Lamellas (membrane) separation unit

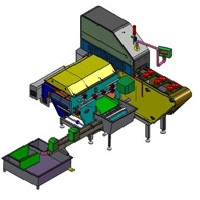

Two Head Aril System

Processing rate : 20-28 pomegranates per minute per extractor.

Extractions rate : About 240-330 kg. Arils per hour, depends on the pomegranates size.

Features : Arils extraction system unit and Water Separation unit

- Manual feeding unit

- The extracting machine

- Air/Water separation unit

- Lamellas (membrane) Separation unit

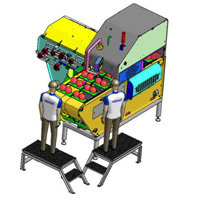

Three Head Aril System

Processing rate : 56 pomegranates per minute per extractor.

Extractions rate : About 670 kg. Arils per hour, depends on the pomegranates size.

Features : Arils extraction system unit and Water Separation unit.

- Manual feeding unit

- The extracting machine

- Air/Water separation unit

- Lamellas (membrane) separation unit

- Electrical control board

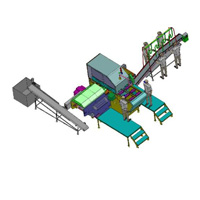

Four Head Aril System

Processing rate : 56 pomegranates per minute per extractor.

Extractions rate : About 670 kg. Arils per hour, depends on the pomegranates size.

Features : Arils extraction system unit and Water Separation unit.

- Manual feeding unit

- The extracting machine

- Air/Water separation unit

- Lamellas (membrane) separation unit

Big Basic Mini Juicer

Processing rate : Up to 28 pomegranates per minute. A machine is for private use: Restaurant/hotels.